Keene State Professor and Students Research Bio-Printing for Tissue Growth

Keene State Assistant Professor of Sustainable Product Design and Innovation Dr. MD Ahasan Habib, and two of his students, are researching bio-printing materials and methods to grow new tissue within a scaffold. The results of the research will benefit people in many ways, including those who are suffering from injury or who have undergone surgery and need to re-build tissue.

“We hope that our research will provide new ways for the healthcare industry to respond to patient needs. We’re thrilled that we’ve already identified two bio-inks that are made up of biomaterials and live cells, to use in the bio-printing process. We are testing these to determine how well cells behave in that material,” said Dr. Habib. “This is truly cutting-edge student research. Through this experience, our students are gaining valuable research knowledge, contributing to solving an important healthcare need, and ultimately, are being be prepared to continue their studies or begin a career in biomedical research.”

Two undergraduate Sustainable Product Design and Innovation students at Keene State, Cartwright Nelson and Slesha Tuladhar, are working on the project with Dr. Habib.

Slesha is working on the rheological properties of the biomaterials. “Rheology is a field of science that studies the flow of liquids. We can simply understand it by looking at water and ketchup. Ketchup is thicker than water, and it needs a certain force to squeeze out. However, biomaterials are quite complex liquids with huge organic molecules. We use a rheometer to measure the viscosity and behavior of biomaterials under different pressure, in the form of graphs and data,” said Slesha. “When I heard about 3D bio-printing, it seemed unreal to me and I wanted to work with it. I don’t know how nature does it – it is so hard to keep a cell alive. Living beings are amazing creations. The entire biology, physics and chemistry of life has to come together while printing the biomaterials and this is the best part about my work.”

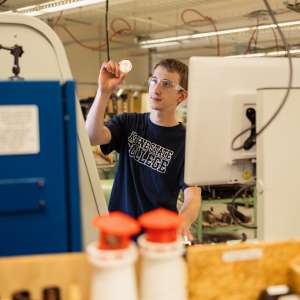

Cartwright has designed, and is now testing, a nozzle system for their existing 3D bio-printer. He said, “I’ve been working with Dr. Habib on bio-printing research since the beginning of this summer, and I have taken on different tasks and methods of research. I began by modeling many different prototypes of a multi-material nozzle system using a CAD program called Rhino. I printed many iterations using Keene State’s Stratasys Dimension 1200es 3D printer, and tested them on our Cellink BioX bioprinter. I ran into some issues with machine precision and quality of prints, so I constructed a nozzle system using medical components. Recently, I’ve been experimenting with the distance it takes for material to transition when switching the extrusion from one material to another. I am now working on analyzing and writing my results. I am interested in this project because of all the knowledge and opportunities I’ve gained from it, such as conference poster presentations.”

The project, which is expected to be completed during the summer of 2021, is funded by The New Hampshire Center for Multiscale Modeling and Manufacturing of Biomaterials (NH BioMade), which advances the design and manufacture of biomaterials.

The NH BioMade Research Seed Funding Opportunity provides support for faculty and post-doctoral associates at New Hampshire universities and colleges to pursue research questions related to the NH BioMade focus areas. NH BioMade is supported by a National Science Foundation EPSCoR award (#1757371.)